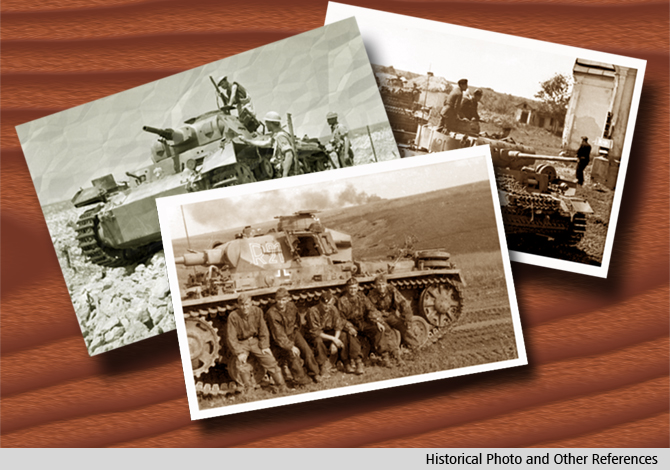

Reference Material

Reference material from various source are needed to verify historical accuracy for each model kit. This information is usually from books, photos, blueprints, museums, and the internet.

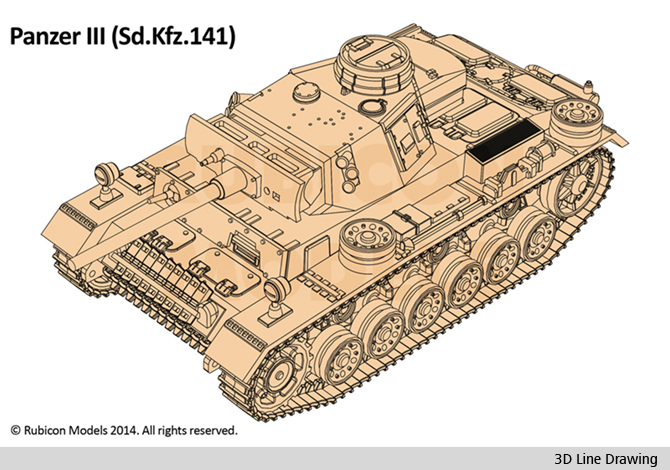

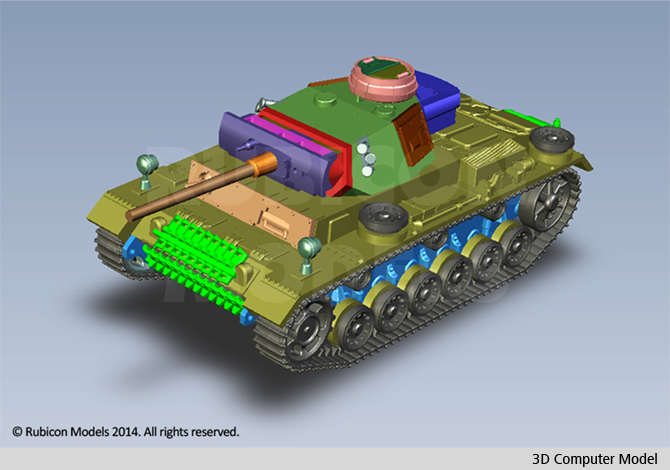

3D Model & Line Drawings

Based on these reference materials, we started to build a scaled 3D model using specialized computer drafting software. Before making a prototype of the model, we had to break the model apart into smaller pieces, more or less the same as what we wanted in the final product.

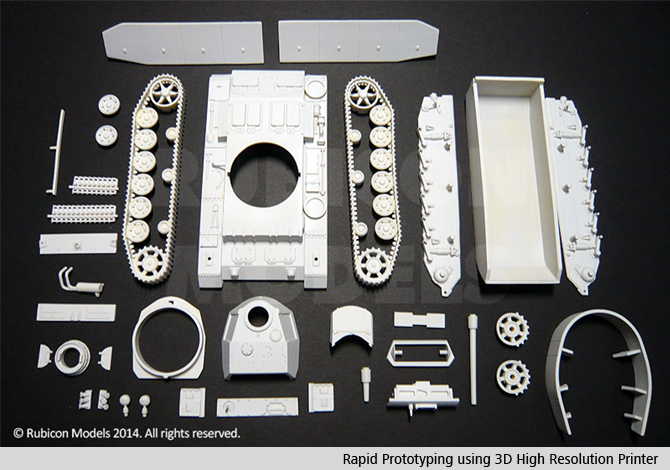

Rapid Prototyping

The model is then being sent to a high resolution 3D printer for rapid prototyping. As the parts are printed, we begin to look into the “human interaction” factor – that is how a modeler would approach building the model using different parts. We will refine the development until our design team is satisfied with the process. We then update the improved 3D model to reflect all the changes made.

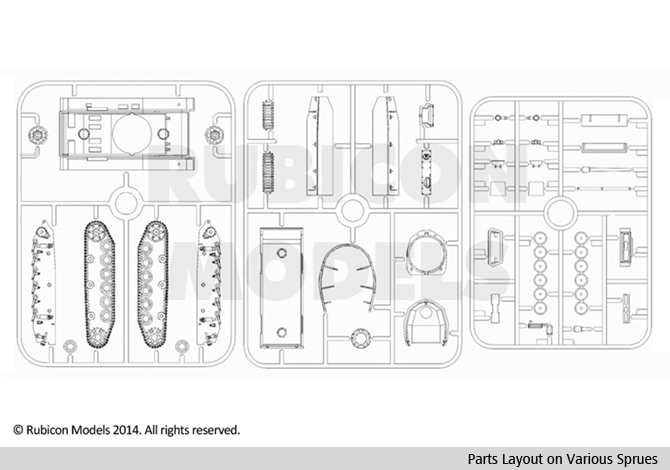

Sprue Layout

Once the 3D model is completed, we will send these parts to specialized software and place all these parts onto a virtual plastic sprue. The software simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects on parts and molds; thus eliminating costly mold rework, improve part quality, and accelerate time to market.

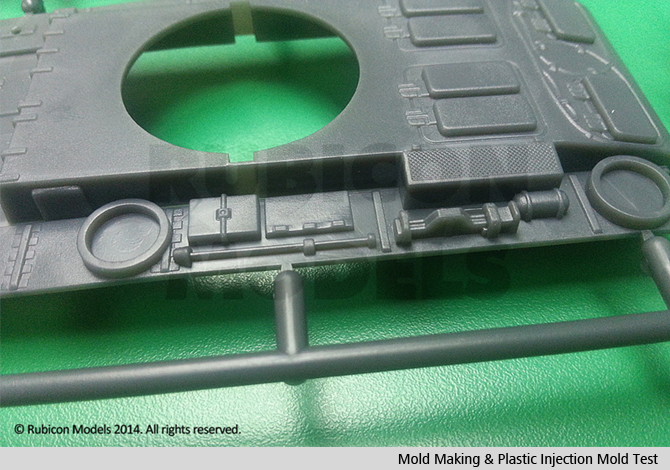

Mold Making

Based on the layout, the sprue is being sent for high precision mold making. After the mold is made, test injection runs are conducted. Sometimes minor adjustments to the molds are needed for optimal results. The process is repeated until everyone is satisfied with the final product. Commercial production can then begin!

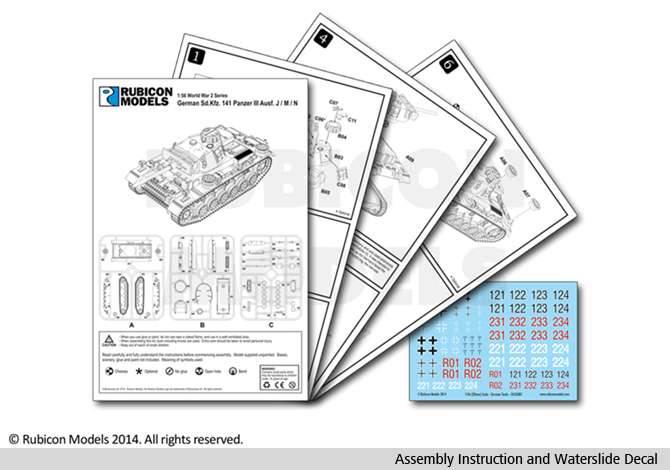

Waterslide Decals

To give a finishing touch to our product range, an extensively research waterslide decal is a must! We have created a variety of decal sheets (by country) for various types of military vehicle.

Assembly Instruction & Packaging

With every quality model kit need a quality instruction sheet. Enormous efforts are spent creating a logical and easy-to-understand multi-page assembly instruction. Eye-catching packaging design is also an integral part of a successful product line!

Important Considerations

In the end, it is not how many details you can put on a model. It all comes to how many parts you actually wanted and if they all fit onto how many sprues! And most important of all… how much you are selling it?

There are always difficult decisions to make:

1) Number of total parts over production cost.

2) Is it too complicated for an average wargamer?

3) Will all parts fit into a standard size sprue?

4) Is this a common feature on the actual vehicle?

5) Which variant(s) should we choose to make?

Hard choices!